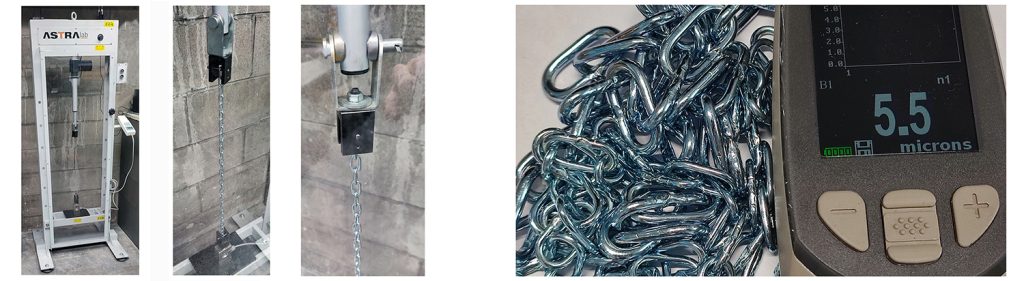

We have incorporated two new quality control tools into our processes: a dynamometer for checking the chain workload and a feeler gauge for measuring the galvanizing coating.

With these sample checks we want to ensure a constant quality of our chains even more accurate and in line with the expectations of the increasingly demanding market on the performance of the products.

WORKING LOAD OF THE CHAIN

Although our chains are included in the “commercial” ones not subject to lifting and traction, we report in the catalogue the indicative workload recommended for each type of article. In this way, the customer has another functional parameter, in addition to the finish and size of the link, to choose the most suitable chain according to their field of application.

With the dynamometer we test randomly if the declared work load of the chain in question is respected without elastic deformation of the single links. We also check the maximum load that the chain is able to withstand before elastic deformation and breakage to get other useful information for our production process.

THICKNESS OF THE GALVANIZING COATING

In the catalogue we declare the minimum thickness of electrolytic zinc coating that covers the chain. In case of special requests from the customer, we open a specific quality plan to have a thicker coating within the external galvanizing process. With the feeler gauge we check the actual thickness on a sample basis to ensure that this corresponds to what is expected. Con lo spessimetro ne verifichiamo a campione l’effettivo spessore per assicurare che questo corrisponda a quanto previsto.

Upon request, we also issue a product certificate with all the characteristics of the chains, attaching it to the delivery note.